The word ‘shim’ evokes different thoughts depending on who hears it. When carpenters hear shim, they likely imagine a wood shim wedge leveling a door. A mechanic pictures a metal slotted shim around a bolt. Noah Katzenstein, Operations Manager and Quality Control for Artus, might picture the Artus Instagram posts with colorful shim stock backdrops.

It’s irrefutable. Shims have many forms and functions. At Artus, we specialize in precision manufacturing plastic and metal shims, shim stock, and motor mount shims. Our shims are custom-made, durable, and ready for nearly any application you throw their way.

So, what is a shim, technically?

Shims can have many creative uses. However, in their essence, shims are flat or wedged materials used to fill in spaces. Different applications require different shim shapes and shim materials, but all share the same primary goals:

- Fill gaps: When assembling systems, parts typically carry buffers in their dimensions. The system accumulates this spacing, known as tolerances. Shims absorb these tolerances and help with the positioning of components. Shims fill accumulated spaces and make parts flush. If parts aren’t flush, the distance between them can cause axial motion and drastically reduce the assembly’s life.

- Level objects: Unlevel equipment may have angular misalignment and fail prematurely. Shims are placed between the two objects to level them and prevent misalignment.

In conclusion, Shims are thin materials that fill unwanted space, reduce wear, position components, and level equipment. Mechanical assemblies, complex equipment, pumps, and motors use shims to fill gaps and level objects. Therefore, shims contribute to the longevity of equipment.

What industries use shims, and what other creative uses have we seen? Read on to learn more.

What are shims used for?

Manufacturing shims

Most of our clients order our rust-resistant, corrosion-resistant shims for industrial equipment. Slotted shims are popular products in the manufacturing industry because they can quickly align motors, pumps, generators, and other machinery on the fly. Slotted shims fit standard bolt sizes and make equipment installation easier and safer.

The recommended practice for machinery installations is to include shims under every support foot. This makes it quicker to repair and adjust down the line. We often deliver shims of multiple thicknesses in bulk to manufacturing companies because they are used frequently. Our color-coding by shim thickness is especially handy in these instances.

Agriculture shims

Machine usage is constantly increasing in the agriculture industry. High-quality shims are used when manufacturing and repairing agricultural machinery to help avoid breakdowns. You can find shims in agriculture machinery with hydraulic and fluid systems, power units, planting and harvesting equipment, processing equipment, conveyor belts, elevators, chemical containment, shafts, bushings, and bearings. Shims are undeniably necessary for modern food production.

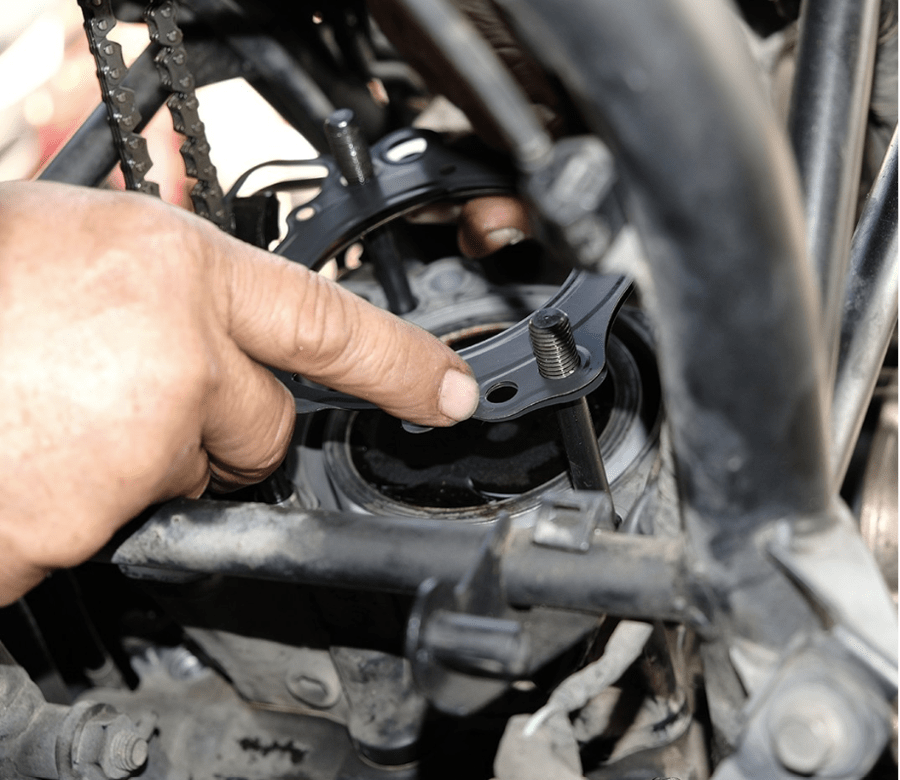

Automotive shims

The automotive industry uses plastic and metal shims because they are wear-resistant and rust-resistant. In automobile manufacturing and maintenance, shims are often used for brake pads, axles, and valves. Brass shims are also used for electric vehicle applications. Artus has worked with numerous automotive companies. Read about our work with Volvo here.

Oil and gas shims

Shims in the oil and gas industry fill tolerance gaps in pumps, valves, and motors, among other uses. Our shims are impervious to oil, which benefits this application.

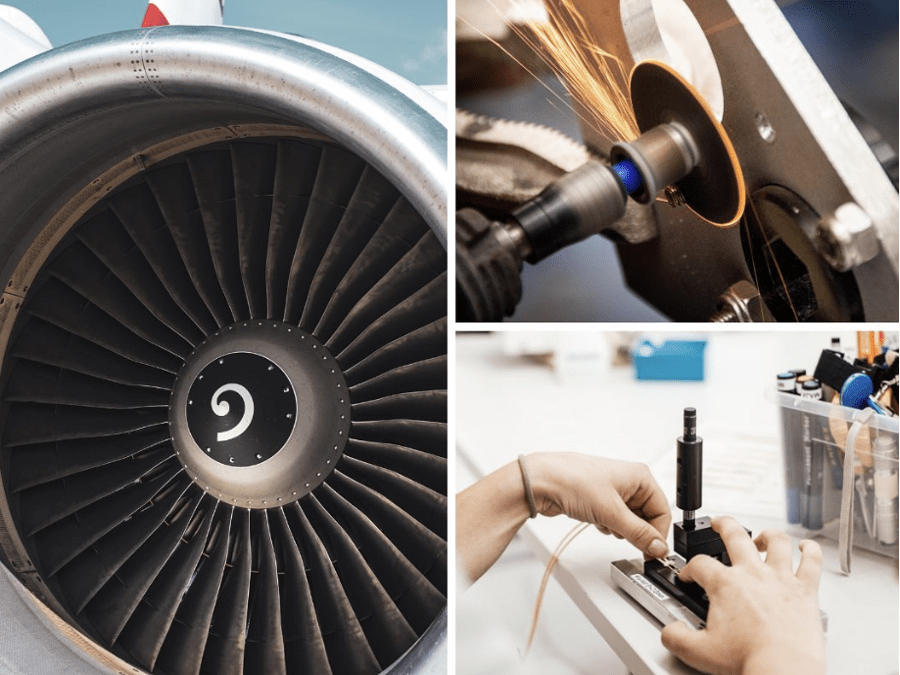

Aerospace shims

The aerospace industry relies on shims for turbine engines, pilot control systems, landing gears, auxiliary power units, hydraulic and fluid systems, and more. Aerospace shims must be durable, corrosion-resistant, wear-resistant, and able to withstand high temperatures to perform correctly at high altitudes. We manufacture metal shims that satisfy the aerospace industry’s ground and airborne demands.

Medical shims

Precision is dire in the medical industry. Shims must be able to withstand adverse conditions and wear. Artus shims are manufactured precisely to meet the tolerances for implantable medical devices, prosthetics, imaging, and surgical equipment.

As you can see, many important industries rely on shims to keep equipment operational and at peak performance. We use manufacturing techniques such as laser cutting, waterjet cutting, and stamping to supply reliable, custom shim products to our customers. Our process is optimized to deliver precision-cut shims, gaskets, and tooling for any application. You can read about Artus’ shim manufacturing process here.

What are the unique uses for shims?

Over the years, Artus has encountered many exciting uses for shims, on top of the applications above:

- NASA used Artus shim stock for machinery that cut tiles for spacecraft pre-Columbia space shuttle.

- Tech companies and startups use our shims for prototyping.

- One of Google’s self-driving car projects featured our shims.

- On our Instagram, you will see thin color-coded shims used as decorations and backdrops.

- Our shims are also popular with gun manufacturers based in the US.

A machine’s reliability depends on the quality of its parts. More than ever, everyday life depends on a growing number of machines. As a result, shims are a crucial part of modern life. It is why many businesses, hobbyists, and Fortune 500 companies turn to Artus for their shim and gasket needs. We have over 80 years of experience supplying quality, precision-cut shim, and gasket solutions.

Contact us today for help finding the right shims for your specific needs. Trust us; we have seen it all!